Install YP18: A Step-by-Step Guide to Ensure Safe and Efficient Operation. Learn about machine specifications, temperature and speed Control, and how to troubleshoot potential issues. This comprehensive guide covers everything from preparation before the operation to circuit diagrams.

SAFETY RULES

A. Safety Advice:

- Please read this manual before use, especially in safety instructions, must comply with safety instructions. Our edge bander is manufactured according to the technology recognized as the most effective and safe in the current market. However, it is still possible to pose a potential danger to users. So, the edge bander should only be used under the following conditions:

- Used by professional personnel or in

- Used in a safe and clean working environment. In any case, make sure that the power supply has Grounded.

- If the machine is out of order, it must power off immediately and pull off the plug before opening the protective Until the problem is removed before powered on again.

- YP18 (additional expansion shelf) are a double-sided edge banding machine and is suitable for the edge-banding operation of various plates such as density plates, particle boards, multi-layer solid wood boards and artificial boards.

- Improper operation is dangerous and should damage the user or damage to the edge bander.

- After-sales and warranty terms are not applicated according to the following.

- Used under Inappropriate environments such as wet, dirty

- Incorrect erection, operation and maintenance.

- Use in the presence of security defects.

- Not recommended for installation, storage, operation, cleaning and maintenance

- To modify or repair edge bander without authorization

- No replacement consumables parts

- In the event of force

B. Security Notification:

- The operation manual must be stored together with the edge

- Comply with the local operation and electrical safety regulations

- The safety mark on the edge bander must be seen and should be replaced immediately if damaged.

C. Electrical Maintenance

- The circuit must be installed, checked and maintained by the electrical

- The electrical parts on the edge banding machine must be checked regularly to prevent loosening.

- It is necessary to make sure that the input voltage is correct. The local voltage shall not exceed ±10%.

- Installation of ground wires as required.

D. Machine Maintenance And Cleaning

- Regular cleaning and maintenance within the recommended time. During the cleaning process, the plug must be removed from the

- Each month, lubricate oil to the transmission parts, such as the chain and gear.

- Should clean the hot melt glue and dust on the edge bander before end up the work every day

Matters Needing Attention

- Turn on the power switch when energized. The thermostat automatically warms up through the self-inspection program.

- Do not place the machine in wet places. Adequate lighting during operation.

- Do not allow children to get close to the edge bander.

- Do not wear a scarf, loose cuff, exposed necklace, or any clothes or bracelets, if possible, to be involved in the edge bander.

- Ensure that the switch is in the “stop-OFF” position before powering on

- Be careful! The melting pot is likely to reach a high temperature of 200. Do not touch the heating range around the melting pot.

- When using the YP18 Portable Edge Banding Machine, it is recommended to use both hands to hold the operation

- Before the operation, confirm that the length of the wire is sufficient and not interfered with.

- Do not touch combustible, explosive material.

- Avoid the heavy moisture room, and it is prohibited to use in the outdoor rain.

- Harmful gases may be produced during use. Using the edge bander in a well-ventilated space or active carbon mask

would be best.

would be best.

- Please keep this manual well to reference spare parts demand and maintenance.

- Switch off the heating and power switch after the work is completed. The machine must be completely cooled before putting into the toolbox.

- Should be cleaned the overflowed hot melt glue left over on the machine at any time

- The melting pot should be well covered immediately after adding hot melt glue to avoid sawdust or debris falling When there is a foreign body in the glue pot, the hot melt glue inside is needed to be replaced. (cool down the edge bander for 2 minutes, or heat up to 80℃, remove the block with tools before the hot melt glue melts) then keep warming up (the engine is not running), and let the rest hot melt glue flow into the melting pot before cleaning up.

- When using hot melt glue at different melting temperature points, please remove the old glue from the melting pot and the glue shaft before adding new hot melt glue.

| Model NO. | YP18 | YP18L |

| Minimum arc diameter | 40MM | 40MM |

| Feeding speed | 0.5-5m/min | 0.5-5m/min |

| Banding tape thickness | 0.3-3.0MM | 0.3-3.0MM |

| Banding tape width | 10-60MM | 10-60MM |

| melting pot volume | 600G | 600G |

| Shape of the workpiece | Straight, Irregular | Straight, Irregular |

| melting temperature | 120-180℃ | 120-180℃ |

| Motor power | 15W | 15W |

| How power | 1020W | 1020W |

| Power supply | 220V/50~60HZ 110V/50~60HZ | 220V/50~60HZ 110V/50~60HZ |

| Net weight | 37KG | 38KG |

| Measurement of the machine | 550×530×560mm | 550×530×560mm |

| Measurement of the package | 63.5×59.5×67CM | 63.5×59.5×67CM |

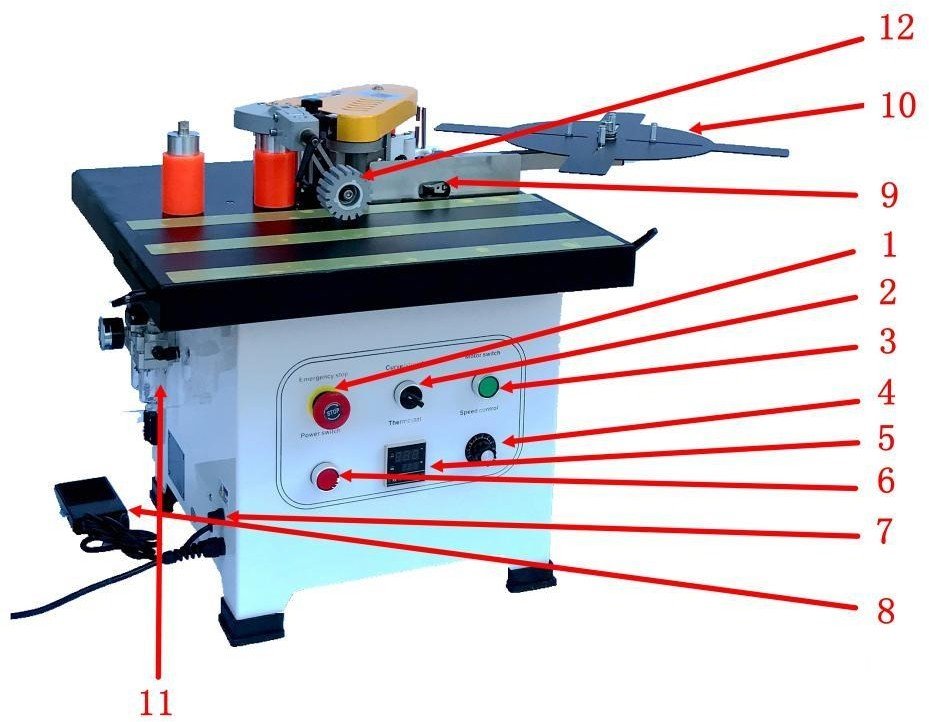

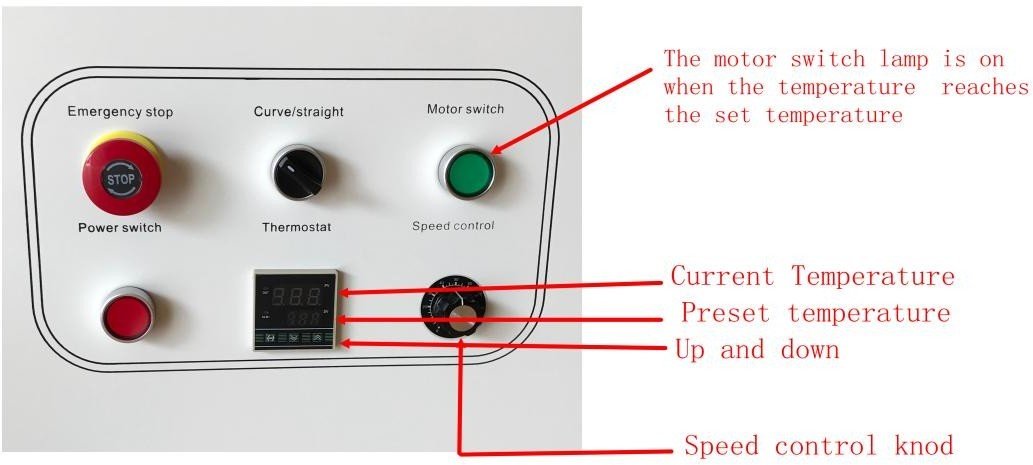

Function Of Each Part

| 1 | Emergency stop switch | Emergency stop machine button |

| 2 | Selected switch | Curved (irregular), straight edge conversion |

| 3 | Motor switch | Control motor start and stop |

| 4 | Speed control knob | Adjust the working speed of edge banding |

| 5 | Thermostat | Temperature control adjustment |

| 6 | Power switch | Control the machine power |

| 7 | Fuse | Protect circuits from overload or short circuit |

| 8 | Foot pedal control | For curved (irregular) edge banding conveyor edge |

| 9 | Limit switch | For straight edge conveyor edge |

| 10 | Feeding plate | Supporting edge tape |

| 11 | Air filter | Gas filtration and gas pressure regulation |

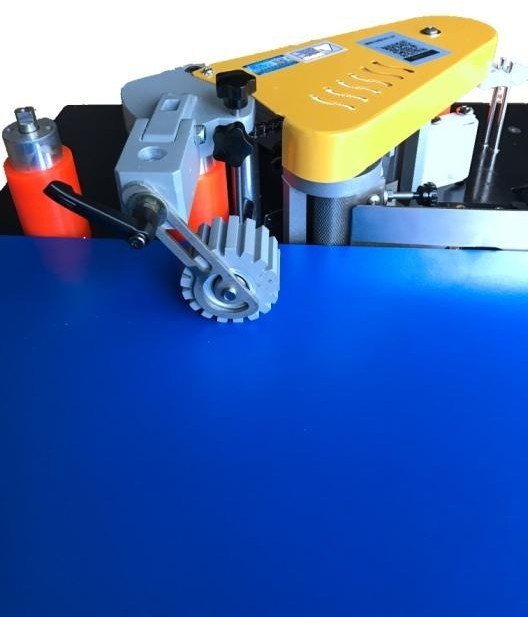

| 12 | Platen wheel | Auxiliary sheet pressure panel |

Preparation Before Operating System

- The machine should be kept clean.

- Wood and materials are to be kept at room temperature.

- When the humidity of the processed material is too high, it will affect the adhesion.

- When Edge bandingYP18 Portable Edge Banding Machine gives the appropriate pressure to the workpiece, not enough pressure will affect the quality of

- Store hot melt glue in a cool, dry

- When Hot melt glue is cool, it should not be forced to open the melting pot cover or the glue adjusting knob to avoid damage to the machine.

- Before edge banding, ensure the hot melt glue in the melting pot is standard.

- The diameter of the inner arc shall not be less than 40mm.

- Please use the low-temperature hot melt glue 120-180 ℃ recommended by our (Maximum temperature shall not exceed 200 ℃)

Temperature And Speed Control

- Optima 2.0 does not have the function of edge tape heating. Opitma2.1 has the function of edge tape heating, which is suitable for heating and softening extremely low temperature or thick sealing strips, making the sealing effect more. Two models can control the edge banding machine, the temperature of the colloid particles of the do adjustment in 120-180 ℃.

- After the power switch is on, the temperature controller displays the current temperature(in red) and adjusts the temperature (in green) through the thermostat panel, the internal relay is switched on, and the light is on. Thermostat with power off memory function, temperature no need to reset after disconnecting the power supply.

- Temperature control indicator: when the heating is started, the light is on.

- Operation indicator: When the temperature reaches the set temperature, the motor switch light will turn on, and the motor switch can be turned on to speed up the gel melting.

- After the motor switch lamp is on, turn on the switch, adjust the adjusting knob to the appropriate speed, and start sealing.

- The curve/straight switch must be closed by the motor switch to work.

Operation Mode

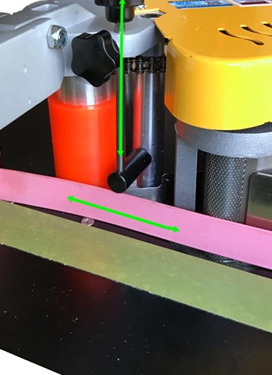

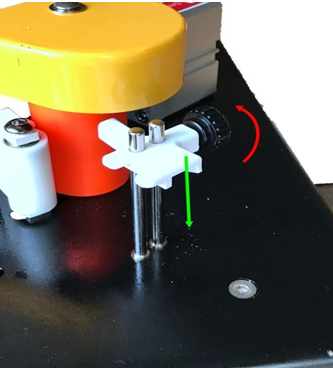

1. Strake height adjustment

- Loosen the knob of the front height limiting device. (picture 1)

- Put the edge in the high limit for measuring pressure to limit the high wing, exposed to the edge, locking the knob. (picture 2 & picture 3)

- About the height of the workpiece, place the workpiece under the platen roller and press down the platen wheel and the workpiece to the main surface of the machine, leaving proper spacing and locking the adjustable handle. Adjust the adjustable handle to release (Figure 4). After the adjustment is completed, then the handle is locked.

Picture 1

Picture 1  Picture 2

Picture 2 Picture 3

Picture 3 Picture 4

Picture 4

2. Adjust the amount of glue

- When the temperature of the edge banding machine reaches the working temperature, cut a piece of edge (about 20CM/8″) into the test, adjust the glue volume knob to the appropriate amount, and let the melt on the edge band be evenly coated

Note that some of the structure is stuck when the hot melt is cooled, and the adjustment knob cannot be turned.

Note that some of the structure is stuck when the hot melt is cooled, and the adjustment knob cannot be turned.

3. Banding tape thickness adjustment: when the edge is too thin or too soft, adjust the thickness by adjusting the knob and fixing the screw to let edge banding perfect.

4. Operation

- When the banding tape is banded to the workpiece, proper pressure should be applied to increase the banding effect.

- After confirming that there is no residue in the edge banding machine, open the starter switch of the edge banding machine. When the hot melt adhesive temperature in the hot melt adhesive cylinder reaches the set temperature, the indicator light (1) of the motor switch button lights up and can be pressed (1). The switch allows the melt cycle to accelerate. According to different hot melt adhesives, waiting for the glue to melt completely is necessary. The processing board is laid flat on the panel, and the wood board is pressed against the limit switch on the stopper. The processing board is close to the glueing shaft, and the starting point of the glueing shaft is about 5 CM. The board’s edge presses down the board, and the edge switch presses the pulley. The cylinder is pressed against the feeding pulley to drive the sealing strip to the shaft. When the sealing strip reaches the driving wheel through the glueing shaft, the processed material is pressurized with moderate pressure and pressed against the driving wheel for edge banding.

Troubleshooting

| Machine can not start | Fuse burn | Replace fuse |

| Glue uneven on the banding tape | 1. Incomplete melting of hot melt glue | Open the melting pot cover to check the hot melt glue |

| 2. Insufficient glue | Adjust gluing knob | |

| 3. The bending stripdeformated | Replace a better edge banding tape | |

| 4. Hot melt glue has not yet been supplied to the glue wheel | Wait a few seconds to start the operation of the engine, waiting for hot melt re-flow to melting pot | |

| Poor adhesion of the banding tape | 1. Non parallel adhesive veneer | Re-calibrate the support plate(refer to page) |

| 2. Heating for a long time, hot melt glue is deteriorated. | Change hot melt glue | |

| 3. Hot melt glue temperature is not the correct temperature | Know the best working temperature of hot melt glue, and adjust the temperature of the machine | |

| Banding tape is not in level | Twist strake attached starting point/push slower than the speed. | The support plate should be flush with the workpiece when pressing and fit the starting point, the edge to the workpiece, can not loose |

| Banding moving tape is not in level | Wheel or feed wheel skid | Clean the belt pulley and the feed wheel |

| Electric start abnormal | Hot melt glue not yet dissolved | Need to re-adjust the temperature, and then start running |

| Indicator normal, but motor does not turn | Motor switch damaged | Replace the motor switch, pay attention to the wiring |

| Abnormal heating | Abnormal heating detection | Please contact the mechanical and electrical professional technician to check whether the temperature drop or short circuit |

For any information or questions on importing woodworking machinery, visit our website https://edgebandmachine.com/ or drop us an email at info@yipteh.com